Top Tips for Choosing the Ideal SRL-Z Series Vertical Mixing Unit

I always recommend choosing a mixing unit that matches your factory's requirements for maximum efficiency and product quality. Selecting the SRL-Z Series Vertical Mixing Unit impacts production outcomes, especially in industries where mixing consistency matters. Industry studies show that the choice of mixing unit influences product quality, energy consumption, and mixing time.

| Mixing Unit Impact | Description |

|---|---|

| Product Quality | Different mixers affect dough quality and performance in industrial baking. |

| Energy Use | Industrial mixers require more energy, influencing costs and results. |

I consider capacity, material compatibility, automation, integration, efficiency, cost, and maintenance essential for making the best choice.

Key Takeaways

- Choose a mixing unit that fits your factory's needs to enhance efficiency and product quality.

- Prioritize mixing consistency and uniformity to ensure high-quality results and reduce production errors.

- Consider automation features that streamline operations and improve workflow efficiency.

- Evaluate the space requirements of the SRL-Z Series to maximize your production area effectively.

- Regular maintenance and cleaning are essential to extend the lifespan of your mixing unit and prevent downtime.

SRL-Z Series Vertical Mixing Unit Overview

Key Features and Benefits

When I evaluate mixing solutions for industrial applications, I always look for equipment that delivers consistent results and supports efficient workflows. The SRL-Z Series Vertical Mixing Unit stands out because it combines high-speed mixing with vertical design. This design saves valuable floor space in busy production environments. I notice that the vertical configuration also helps achieve uniform mixing, which is essential for producing high-quality materials.

Some of the key features I find most valuable include:

- High-speed mixing capability for rapid batch processing

- Robust stainless steel construction for durability and hygiene

- Advanced temperature control systems to protect sensitive materials

- User-friendly controls that simplify operation and monitoring

Tip: I recommend choosing a model with an integrated cooling system if you process heat-sensitive materials. This feature helps maintain product quality and reduces the risk of overheating.

Compared to horizontal mixers, the SRL-Z Series Vertical Mixing Unit offers better space utilization and often delivers more consistent mixing results. I have seen factories benefit from the vertical design, especially when floor space is limited or when they require frequent cleaning and maintenance.

Common Industrial Applications

I often see the SRL-Z Series Vertical Mixing Unit used in a variety of industries. These units handle tasks such as blending PVC, plastics, and other polymer materials. Manufacturers in the chemical, plastics, and food processing sectors rely on these mixers for their ability to process large batches efficiently.

| Industry | Typical Use Case |

|---|---|

| Plastics | PVC compound mixing |

| Chemicals | Powder and granule blending |

| Food Processing | Ingredient homogenization |

I recommend this unit for any operation that demands reliable, high-capacity mixing with minimal downtime. The SRL-Z Series Vertical Mixing Unit adapts well to automated production lines, making it a smart investment for modern factories.

Defining Mixing Needs

Mixing Consistency and Uniformity

I always start by evaluating how well a mixing unit can deliver consistent and uniform results. In my experience, the SRL-Z Series Vertical Mixing Unit stands out for its high-precision mixing. The dual-shaft design blends materials thoroughly, which is essential for industries like plastics, chemicals, and pharmaceuticals. I have seen how this level of consistency ensures that every batch meets strict product specifications.

- The dual-shaft system enhances efficiency and produces even results.

- Consistent mixing leads to higher product quality and fewer production errors.

- Uniformity is critical when working with sensitive or high-value materials.

Tip: I recommend prioritizing mixing consistency if your process requires strict quality control. This approach reduces waste and improves overall output.

Batch Size and Output

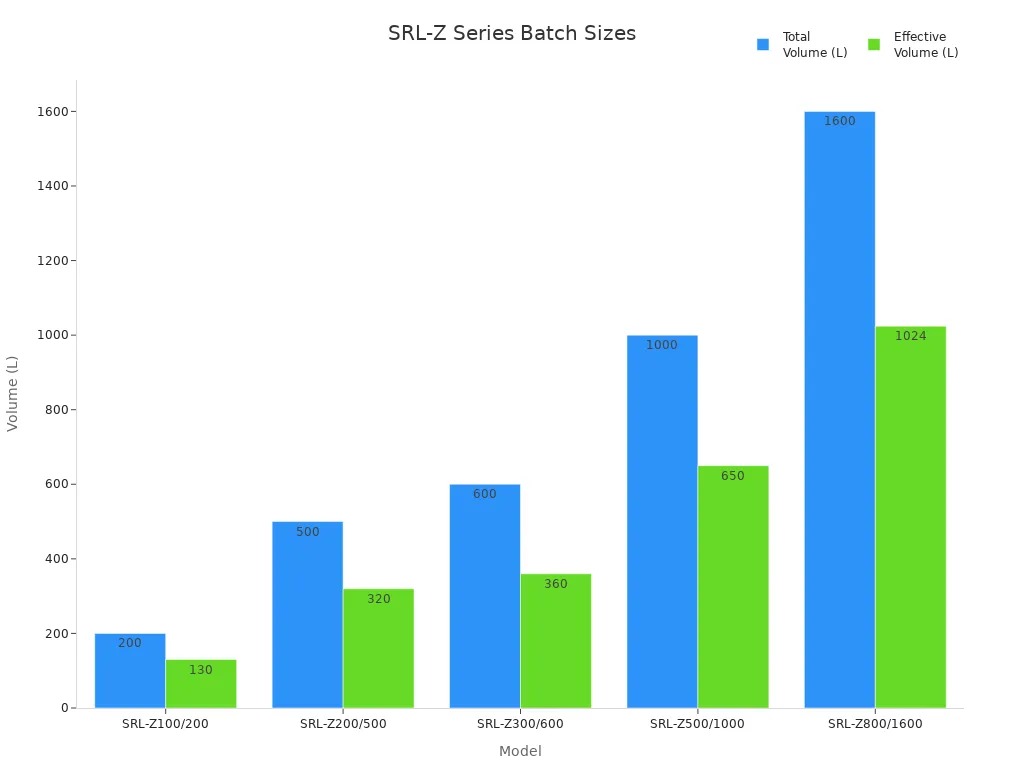

I always assess the required batch size before selecting a mixing unit. The SRL-Z Series Vertical Mixing Unit offers a range of models to suit different production needs. I use the following table to compare total and effective volumes for each model:

| Model | Total Volume (L) | Effective Volume (L) |

|---|---|---|

| SRL-Z100/200 | 100/200 | 65/130 |

| SRL-Z200/500 | 200/500 | 150/320 |

| SRL-Z300/600 | 300/600 | 200/360 |

| SRL-Z500/1000 | 500/1000 | 375/650 |

| SRL-Z800/1600 | 800/1600 | 600/1024 |

I match the model to the amount of material I need to process per batch or hour. This step helps me avoid inefficiencies and ensures that the mixer can keep up with production demands. I also consider the mixing time and efficiency, which depend on the design of the mixing screw, motor power, and speed.

Material Compatibility

I always check material compatibility before making a final decision. The SRL-Z Series Vertical Mixing Unit handles a wide range of materials, which makes it suitable for many manufacturing environments. I use the following table to review compatible materials:

| Compatible Materials | Description |

|---|---|

| PVC Compounds | Ideal for mixing and processing PVC materials. |

| Degradable Plastics | Supports the blending of environmentally friendly plastics. |

| Specialty Profiles | Designed for unique material profiles in various applications. |

I often mix PVC powder for extrusion lines and process various plastic raw materials. The mixer's high-performance capabilities also support thermoplastics and specialty profiles. I always ensure that the mixer's construction material and build quality meet industry standards for safety and hygiene.

Note: I recommend verifying the specific requirements of your materials with the manufacturer to ensure optimal performance and longevity.Please feel free to contact us at info@audop.com.

Integration and Automation

Automation Features

I always look for automation features that simplify my workflow and boost efficiency. The SRL-Z Series Vertical Mixing Unit uses a fully automated system to manage both mixing and cooling. When I load materials into the heat mixer, a spiral loader handles the process automatically. The system monitors temperature closely. Once the materials reach the set temperature, it transfers them to the cooling mixer without manual intervention. This automation streamlines my operations and gives me precise control over temperature settings. I see fewer errors and less downtime because the process runs smoothly from start to finish.

Automation helps me maintain consistent product quality and reduces labor costs. I recommend choosing a unit with a reliable automatic operation system for any busy factory.

Integration with Production Lines

I always consider how well a mixing unit fits into my existing production line. The SRL-Z Series Vertical Mixing Unit integrates seamlessly with modern factory setups. I benefit from its dual functionality, which combines heating and cooling in one unit. This design saves time and space. The advanced two-layer sealing system prevents contamination, keeping my materials clean throughout the process. The automatic workflow allows me to control mixing and cooling with precision, making it easy to connect the unit to other equipment.

Here are some ways I use this mixer in my production lines:

- I ensure consistent product quality in PVC pipe production by evenly distributing raw materials.

- I achieve uniform color and filler distribution during masterbatch granulating, which leads to high-quality granules.

- I lay the foundation for strong mechanical properties in modified plastics by mixing thoroughly.

I recommend reviewing your production line layout before installation. Proper integration helps maximize efficiency and supports smooth operations.

User Controls and Monitoring

I always check the user controls and monitoring options before choosing a mixing unit. The SRL-Z Series Vertical Mixing Unit offers user-friendly controls that make operation simple. I can adjust settings quickly and monitor the process in real time. The control panel displays key information, such as temperature and mixing time. This helps me respond to changes and maintain optimal conditions. I find that clear controls reduce training time for new staff and minimize mistakes.

- Easy-to-read displays show important data.

- Intuitive buttons and switches allow fast adjustments.

- Real-time monitoring helps me catch issues early.

I suggest selecting a unit with advanced monitoring features if you want to improve process reliability and reduce downtime.

Space and Layout

Floor Space Requirements

When I plan a new mixing unit installation, I always measure the available floor space first. The SRL-Z Series Vertical Mixing Unit features a vertical design, which helps me save valuable space in my production area. I find that this design allows me to fit the mixer into tighter spots compared to horizontal mixers. I recommend checking the unit's footprint and comparing it to your factory layout.

Here is a quick reference table I use to estimate space needs for different models:

| Model | Approx. Footprint (m²) |

|---|---|

| SRL-Z100/200 | 2.5 |

| SRL-Z200/500 | 3.2 |

| SRL-Z300/600 | 3.8 |

| SRL-Z500/1000 | 4.5 |

| SRL-Z800/1600 | 5.2 |

Tip: I always leave extra space around the unit for safe movement and maintenance access. This practice helps prevent accidents and makes cleaning easier.

I also consider the height of the unit. The vertical structure means I need to check for overhead clearance, especially if I have low ceilings or overhead piping.

Installation and Accessibility

I always plan the installation process before the unit arrives. I make sure the delivery path is clear and the foundation is strong enough to support the mixer's weight. I prefer to install the SRL-Z Series Vertical Mixing Unit near raw material storage and production lines. This setup reduces transport time and improves workflow.

For accessibility, I check that all service points are easy to reach. I look for features like wide access doors, removable panels, and clear control panels. These details make routine checks and cleaning much faster.

- I keep walkways clear for operators and maintenance staff.

- I ensure emergency stops and safety switches are visible and within reach.

I recommend reviewing your factory's layout with your team before installation. Good planning helps avoid costly changes later and keeps your operation running smoothly.

Construction and Safety

Build Quality

I always pay close attention to the build quality of any mixing unit I select for my factory. The SRL-Z Series Vertical Mixing Unit uses premium materials that guarantee durability and long service life. I see how the aluminum alloy mixing bowl and discharge port provide both strength and a lightweight design. This combination makes installation easier and reduces wear over time. The customizable stainless steel covers add another layer of protection, resisting corrosion and frequent cleaning cycles.

I rely on a multi-level main shaft seal structure to prevent leaks and extend the lifespan of the equipment. The precision blade structure ensures every batch mixes evenly, which is essential for maintaining product quality. I notice that the internal surfaces are polished or sandblasted. This finish prevents material from sticking and makes cleaning faster. Motors with copper cores deliver reliable power and match the rated performance needed for heavy-duty mixing.

| Component | Material Used | Purpose |

|---|---|---|

| Mixing Bowl and Discharge Port | Customizable Stainless Steel | Ensures strength and lightweight design. |

| Mixing Bowl Covers | Customizable Stainless Steel | Provides durability and resistance to wear. |

| Main Shaft Seal Structure | Multi-level framework | Prevents leakage and extends lifespan. |

| Blade Structure | Precision Design | Ensures uniformity and effective mixing. |

| Internal Surface | Polished/Sandblasted | Prevents material sticking for longevity. |

| Motors | Copper-core | Aligns rated power with performance. |

I recommend inspecting these components regularly to maintain optimal performance and avoid unexpected downtime.

Safety Features

I always make safety a top priority when choosing mixing equipment. The SRL-Z Series Vertical Mixing Unit includes features that meet international standards and protect my team during operation. Emergency stop buttons comply with ISO 13849-1, allowing operators to halt the machine instantly if needed. This feature reduces the risk of accidents and keeps everyone safe.

Safety latches also meet ISO 13849-1 requirements. These latches secure access points and prevent accidental opening during mixing cycles. I find that these features create a safer working environment and help my factory meet certification standards.

| Safety Feature | Compliance Standard | Impact on Safety |

|---|---|---|

| Emergency Stop | ISO 13849-1 | Reduces accident risk significantly |

| Safety Latches | ISO 13849-1 | Enhances safety in certified environments |

I always train my staff to use these safety features correctly. Proper training ensures everyone knows how to respond quickly and keeps operations running smoothly.

Maintenance and Cleaning

Routine Maintenance

I always prioritize routine maintenance to keep my SRL-Z Series Vertical Mixing Unit running smoothly. Regular checks and cleaning help me avoid unexpected downtime and extend the lifespan of the equipment. I follow a clear schedule for each maintenance task. Here is a table I use to organize my routine:

| Maintenance Task | Frequency | Details |

|---|---|---|

| Cleaning Protocols | Daily | Use purge compounds between material changes |

| Cleaning Protocols | Weekly | Perform ultrasonic cleaning for carbon buildup |

| Cleaning Protocols | Monthly | Inspect screw flights for wear (max 0.5mm clearance) |

| Heater Band Optimization | Monthly | Monitor resistance values (deviation ≤ 10%) |

| Heater Band Optimization | Immediate | Replace cracked ceramic insulators |

| Gearbox & Drive Maintenance | Every 500 hrs | Oil analysis for iron particles and viscosity change |

I check the screw flights every month. If I see more than 0.5mm clearance, I schedule repairs. I monitor heater bands for resistance changes. If I find a cracked ceramic insulator, I replace it right away. I also analyze gearbox oil every 500 hours to catch early signs of wear.

Tip: I keep a maintenance log to track each task. This habit helps me spot patterns and plan for future service.

Cleaning Procedures

I clean my mixing unit every day. I use purge compounds when I switch materials. This step prevents contamination and keeps my batches consistent. Once a week, I perform ultrasonic cleaning. This method removes carbon buildup from hard-to-reach areas. I inspect all surfaces for residue and make sure the discharge port stays clear.

I always wear protective gloves and goggles during cleaning. I follow the manufacturer's guidelines for cleaning agents. I avoid harsh chemicals that could damage the mixing bowl or seals.

- I use soft brushes for internal surfaces.

- I rinse with warm water after each cleaning cycle.

- I dry all parts thoroughly before restarting the unit.

I recommend scheduling deep cleaning during planned downtime. This approach keeps production on track and ensures safety.

Spare Parts and Support

I rely on strong after-sales support for my SRL-Z Series Vertical Mixing Unit. Major suppliers offer quick access to spare parts and technical assistance. I know that engineers are available to service machinery overseas, which gives me peace of mind. The standard warranty lasts 12 months, so I feel confident about long-term reliability.

| After-sales Service Provided | Warranty |

|---|---|

| Engineers Available To Service Machinery Overseas | 12 Months |

I keep essential spare parts on hand, such as heater bands and seals. I contact support if I need help with troubleshooting or repairs. Fast response times help me minimize downtime and maintain high productivity.

I suggest building a relationship with your supplier. Reliable support ensures your mixing unit stays in top condition year-round.

Budget and ROI

Upfront and Operating Costs

When I evaluate a new mixing unit, I always start by calculating both the initial investment and the ongoing expenses. The purchase price covers the mixer, installation, and any required accessories. I also factor in costs for training my team and setting up the workspace. Operating costs include electricity, routine maintenance, and spare parts. I track these expenses closely to avoid surprises later.

| Cost Type | Example Expenses |

|---|---|

| Upfront | Equipment, installation, training |

| Operating | Electricity, maintenance, parts |

I recommend requesting a detailed quote from your supplier. This step helps you plan your budget accurately and prevents hidden costs.Please feel free to contact us at info@audop.com.

Energy Efficiency

I always look for equipment that helps me save on energy bills. The SRL-Z Series Vertical Mixing Unit uses advanced motors and efficient heating systems. These features reduce power consumption during both mixing and cooling. I monitor my energy usage every month. Lower energy use means lower operating costs and a smaller environmental footprint.

- Efficient motors cut down on electricity bills.

- Smart temperature controls prevent energy waste.

- Reduced energy use supports sustainability goals.

I suggest comparing the energy ratings of different models before making a final decision.

Long-Term Value

I focus on long-term value when I invest in new machinery. The SRL-Z Series Vertical Mixing Unit offers durability and reliable performance. I see fewer breakdowns and less downtime, which means higher productivity. The robust construction and easy maintenance extend the service life of the unit. I calculate my return on investment by tracking output, quality, and maintenance costs over time.

- Durable design lowers replacement frequency.

- Reliable operation boosts overall output.

- Easy maintenance keeps the unit running smoothly.

I recommend reviewing performance data after six months to measure your ROI and adjust your maintenance plan if needed.

I always review these essential tips before choosing any SRL-Z Series Vertical Mixing Unit. I focus on capacity, material compatibility, automation, integration, efficiency, cost, and maintenance. I use this checklist to guide my decision and ensure the best fit for my factory.

- I recommend consulting with suppliers for tailored advice and integration support.

FAQ

What materials can I mix with the SRL-Z Series Vertical Mixing Unit?

I use this unit for PVC, degradable plastics, and specialty profiles. The mixer handles powders, granules, and thermoplastics. I always check with the supplier for specific compatibility before starting a new material.

How do I maintain the SRL-Z Series Vertical Mixing Unit?

I follow a daily cleaning routine and inspect key parts monthly. I keep a maintenance log to track tasks. I replace worn components quickly. Regular oil analysis helps me prevent gearbox issues.

Tip: Schedule deep cleaning during planned downtime for best results.

Can I integrate this mixer with my automated production line?

I connect the SRL-Z Series Vertical Mixing Unit directly to my automated systems. The unit supports automatic loading, mixing, and cooling. I review my production layout before installation to ensure seamless integration.

What safety features does the SRL-Z Series Vertical Mixing Unit offer?

I rely on emergency stop buttons and safety latches that meet ISO 13849-1 standards. These features protect my team and help me comply with industry regulations.

| Safety Feature | Standard |

|---|---|

| Emergency Stop | ISO 13849-1 |

| Safety Latches | ISO 13849-1 |

How do I get spare parts or technical support?

I contact my supplier for spare parts and technical help. Engineers provide service overseas. I keep essential parts on hand and use the 12-month warranty for peace of mind. Fast support keeps my production running smoothly.